Optimise Production, Simplify Processes, and Elevate Business Performance with ERPNext Manufacturing ERP

The manufacturing industry is among the fastest-growing sectors globally. Leveraging data and product innovation, ERPNext Manufacturing software is designed to meet the diverse needs of manufacturing businesses of all sizes and types. This cloud-based ERP solution offers industry-specific features and capabilities to manage, control, track, automate, and collaborate across every stage of the manufacturing process seamlessly.

ERPNext Manufacturing software enhances organizational efficiency and boosts productivity by automating workflows and optimizing inventory management. Our open-source ERP solution is tailored to address industry challenges while exceeding client expectations. SolufyERP’s ERPNext delivers cutting-edge solutions for manufacturers, supporting configure-to-order, make-to-order, and assemble-to-order product strategies.

Benefits of ERPNext Manufacturing Software

Manage Operations

- Lower Production Expenses

- Strengthen Data Protection

- Gain Complete Production Oversight

- Simplify Forecasting and Reporting

- Optimize Cash Flow Management

- Enhance Customer Relationship Management (CRM)

- Improve Operational Flexibility

- Automate the Entire Workflow

Features of ERPNext Manufacturing

With customizable open-source ERPNext software, you can effortlessly adapt and refine internal processes to align with your unique business needs

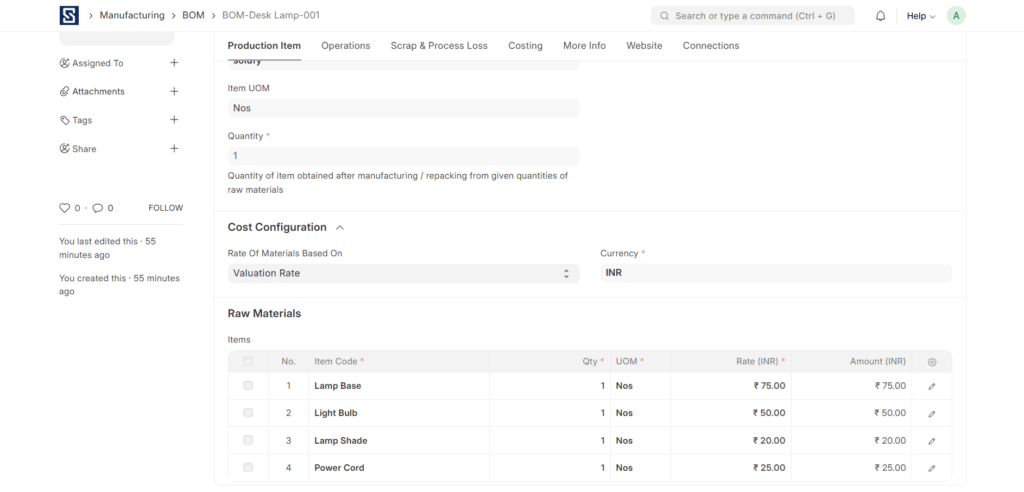

Bill of Materials (BOM)

- Generate, View, and Print Product Bills

- Customize Quantity, Cost, Descriptions, and Item Codes

- Detailed Workstation Functionality

- Create Work Orders and Define Procurement Types

- Manage Routing Codes and Operations

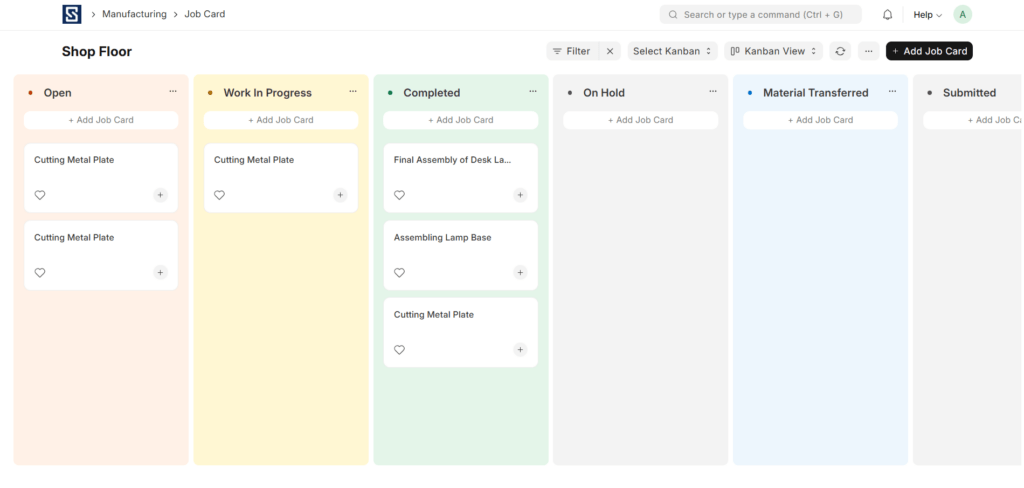

Shop Floor Management

- Workstation Capabilities

- Monitor Workstation Locations

- View Real-Time Status Updates

- Log Activities and Track Manufactured Products

- Manage Employee Assignments and Task Distribution

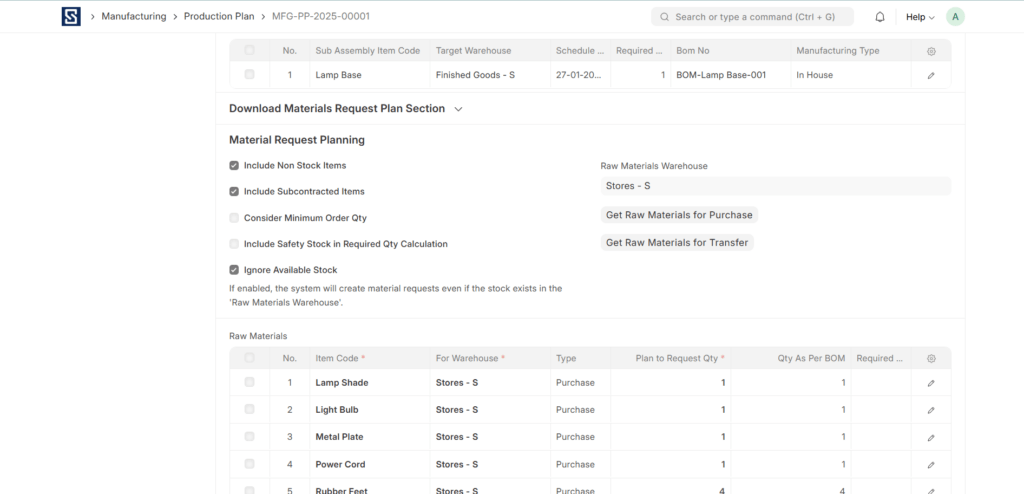

Material Requirements Planning (MRP)

- Link Base Prices to Material Requests

- Cost Calculation Tool

- Track Purchase Records and Manage Inventory

- Monitor Manufacturing Capacity and Production Progress

- Automate Stock Valuation and Quantity Tracking

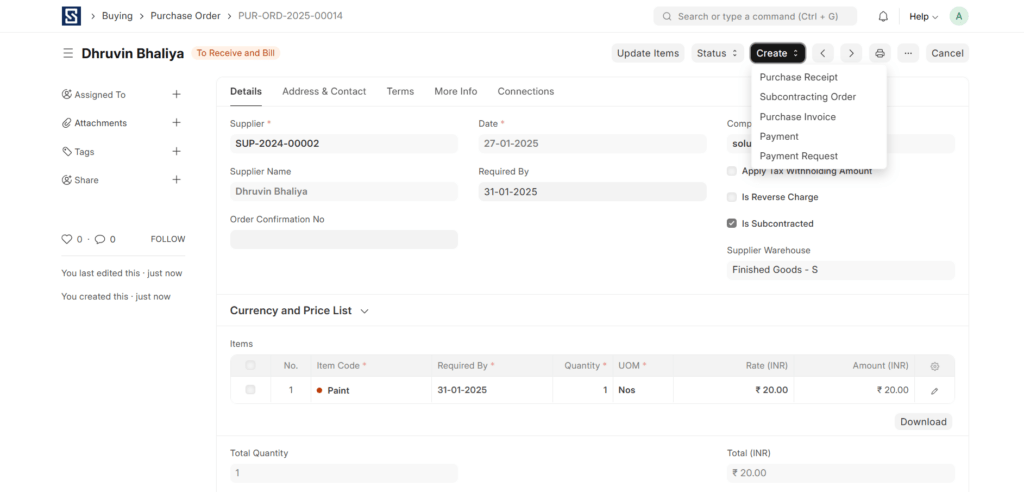

Subcontracting

- Collaborate with Multiple Suppliers and Vendors

- Oversee Daily Operations

- Expedite Raw Material Supplies

- Avoid Stock Shortages

- Track Labor and Procured Services

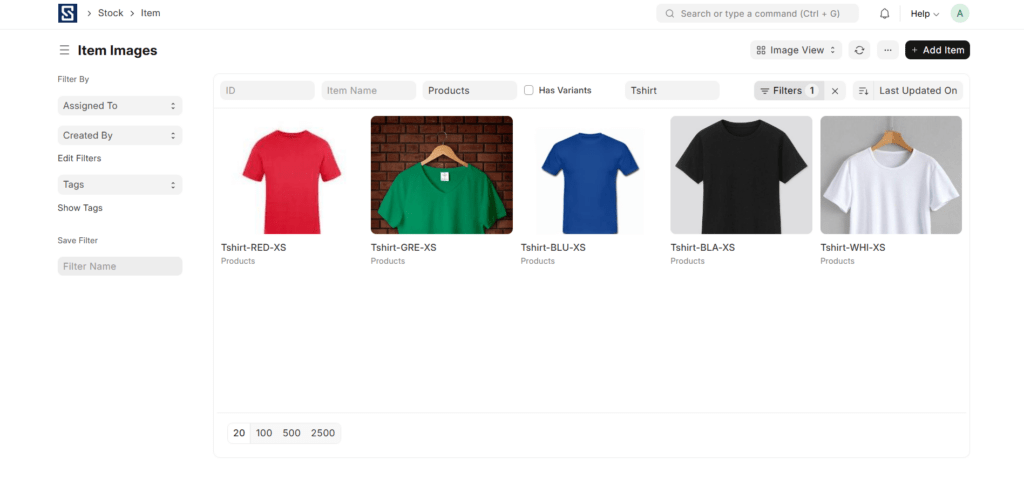

Item Variants

- Create Item Templates

- Manage Size and Shape Variations

- Map Variant Attributes

- Automatically Generate SKUs for Stocked Variants

- Generate Multiple Stock Requests

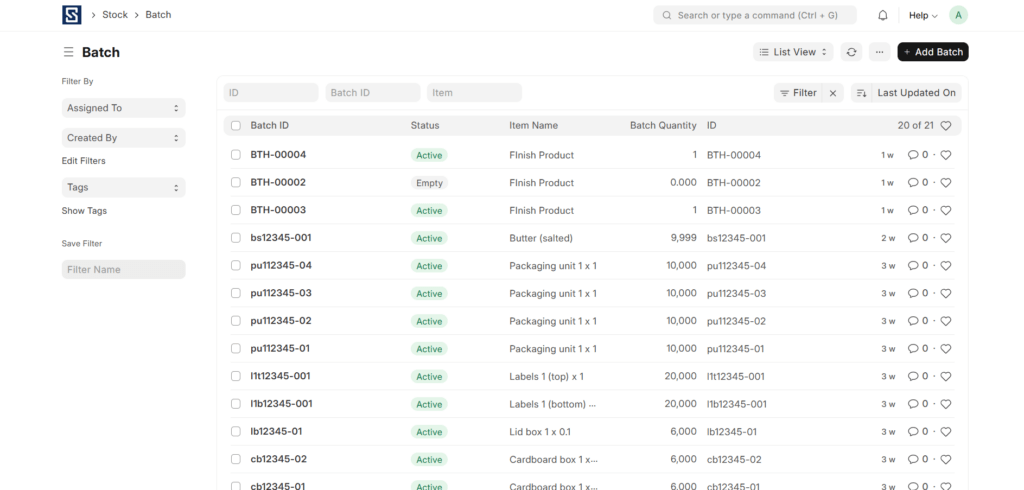

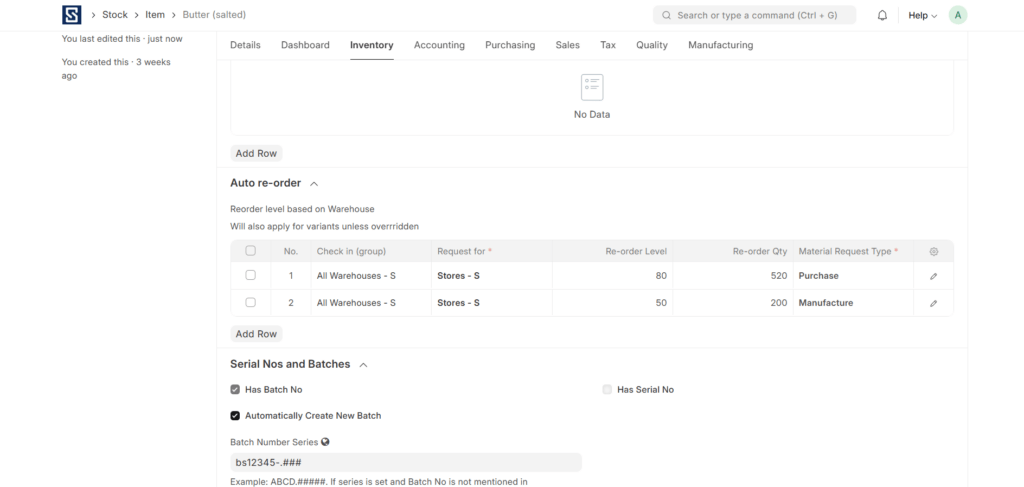

Batched & Serialized Inventory

- Set Prerequisites and Auto-Create Batches

- Assign and Automatically Generate Serial Numbers

- Split Batches Based on Manufacturing and Expiry Dates

- Add Scannable Item Barcodes and Batch Descriptions

- Enable Barcode Scanning for Product Entries

- Advanced Filtering Options in List View

- View Active, Pending, and Delivered Stock Units

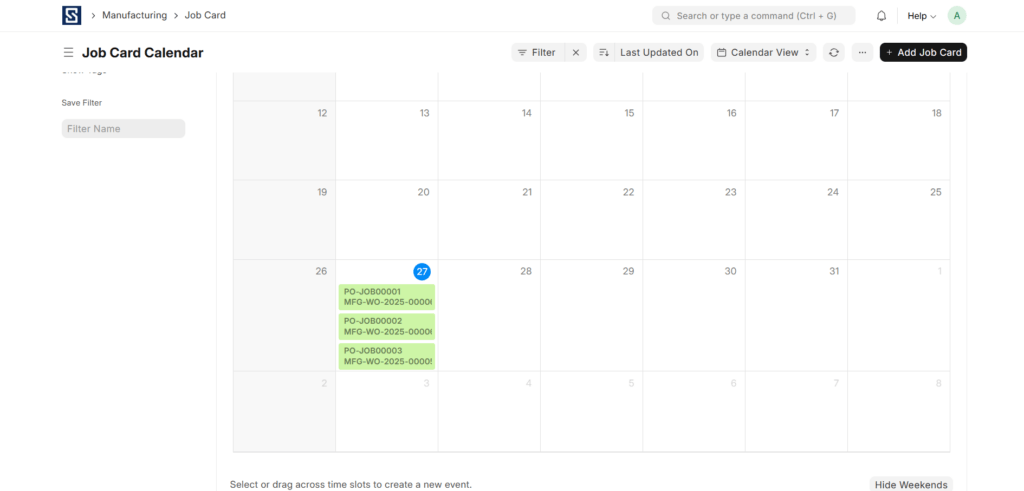

Capacity Planning

- Set Pre-defined Item Orders on the Calendar

- Track Updated Due Dates for Deliverable Items

- Manage Scheduling and Work Orders

- Monitor Production Dates, Batch Codes, and Timelines

- Oversee Functional Operations and Associated Activities

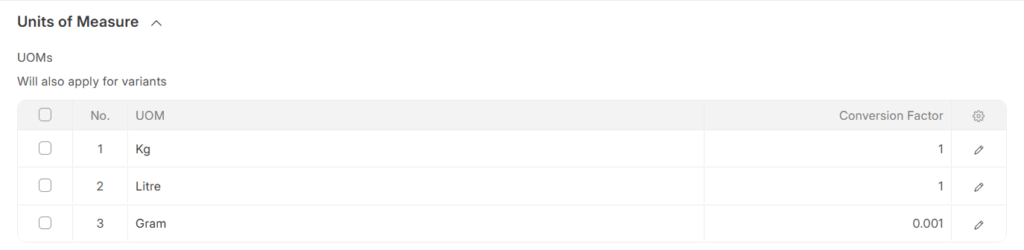

Unit of Measurement (UoM)

- Material Measurements: Serial Number, Batch Number, and Variants

- Add Multiple Unit of Measure (UOM) for Products

- UOM Conversion Factors and Auto Conversion

- Sales, Purchase, Warehouse, and Accounting Information

- Product Transaction History and Details

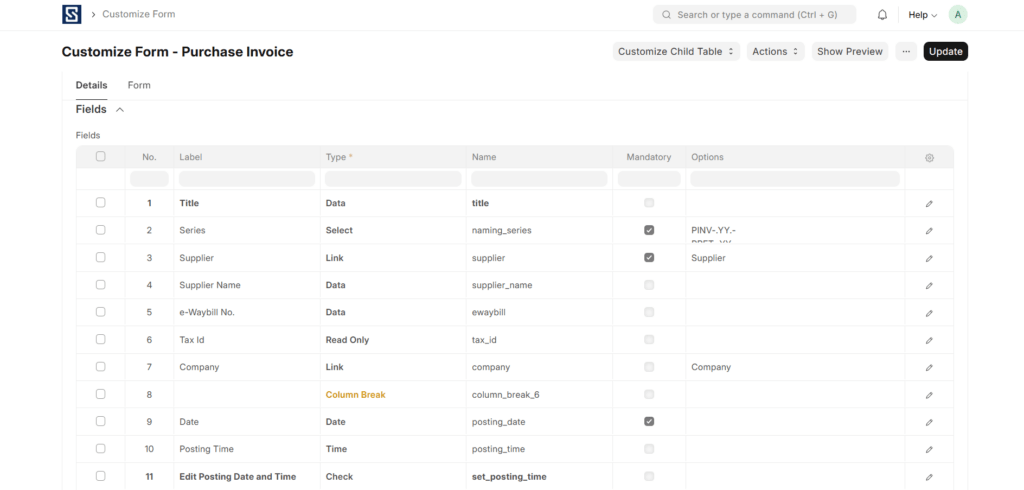

Easy Customization

- Design and Create Custom Bill and Order Forms

- Multilingual Support for Manufacturing ERP

- Customize Plan Title, Form Type, and Image Fields

- Add Searchable Keywords for Easy Access

- Manage Change Tracking, Hide Fields, and Enable Quick Entries

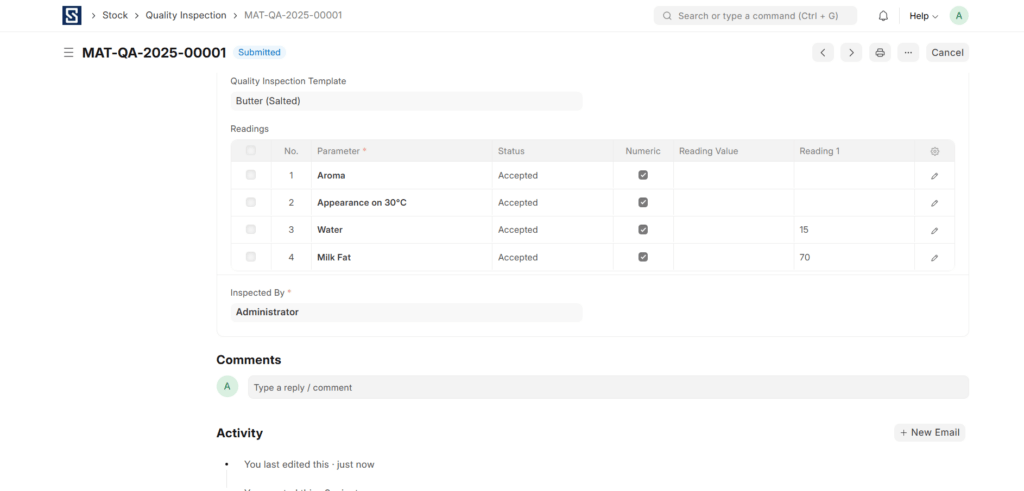

Quality Assurance

- Quality Control (QC) Characteristics and Features

- Item Testing Parameters and Processes

- Incoming Quality Control (IQC)

- Item Test Relationships

- Alerts and Notifications Management

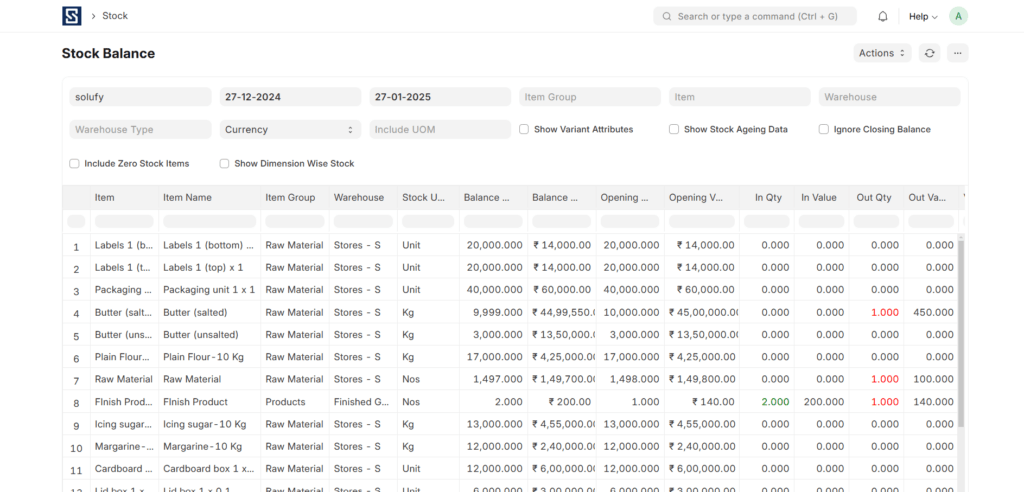

Stock Balance and Replenishment

- Warehouse Stock Estimation and Forecasting

- Monitor and Receive Alerts for Stock Levels

- Simplified Stock Valuation for Easy Management

- Display Item Code, Name, and Warehouse Information

- Update Item Barcodes and Images on the Dashboard

Inventory Control

- Inventory Forecasting and Strategies

- Product Tagging and Categorization

- Restocking Requests and Information

- Dispatch Scheduling Workflow

- Storage and Organization Solutions

Conclusion

It is a game-changer for manufacturers looking forward to optimising production, enhancing operational efficiency, and embracing automation. With industry-specific features such as Material Requirements Planning (MRP), Shop Floor Management, Quality Assurance, and Inventory Control, ERPNext enables business improvements through streamlined workflows, cost reductions, and better decision making. With the expertise from SolufyERP, manufacturers can tweak and adapt ERPNext to uniquely meet their business needs, hence maximise ROI and sustain growth. Unlock the full potential of your manufacturing processes with ERPNext—the trusted ally for innovativeness and efficiency.