In the speedy and active life of engineering, efficiency, precision, and modernisation are vital to wining the competition. These firms can range from managing hundreds of complex projects to inventory management, quality control, and compliance. All these different tasks certainly have their complications. ERPNext is an open-source enterprise resource planning (ERP) system that acts as an all-in-one solution to streamline and enhance productivity in engineering organisations.

Why ERPNext for Engineering?

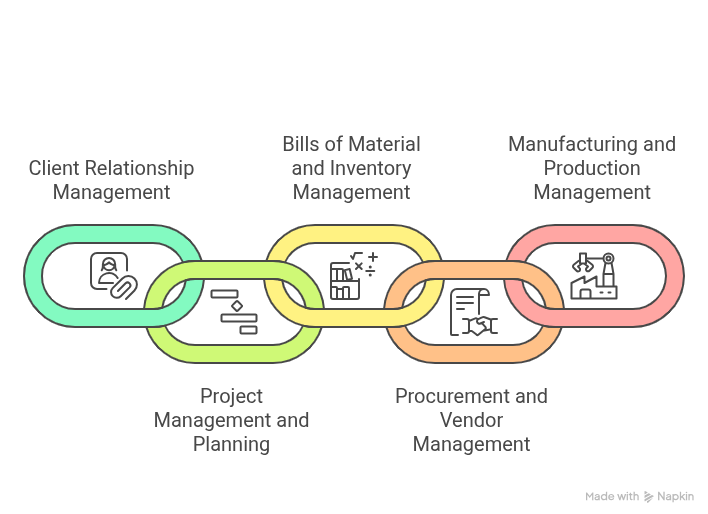

ERPNext is also a comprehensive platform used for integrating and joining different elements of the business functions, such that engineering industries will manage the operation a bit easier with its modern-day effects. Here are the benefits of ERPNext to an engineering business:

1. Client Relationship Management (CRM)

Engineering firms must maintain very good relationships with customers. The CRM module of ERPNext contains:

Lead and opportunity management.

Customer support and ticketing system.

Automated follow-ups and contract management.

Sales pipeline tracking.

Customer complaints handling and warranty claims.

Centralized customer database for personalized service.

2. Project Management and Planning

Engineers involve multiple phases, stakeholders, and timelines. The project management module of ERPNext enables the firms to:

Plan and schedule multiple projects effectively.

Milestones, deadlines, and deliverables tracking.

Allocation of resources and workload management.

Monitoring costs against budgets in real time.

Team collaboration through a centralized dashboard for planning activities.

Delegate tasks and track the progress of activities through a Gantt chart and Kanban board.

3. Bills of Material (BOM) and Inventory Management

Engineering, in a nutshell, is raw materials, spare parts, and finished goods. ERPNext helps you by allowing you to:

Create and manage multi-level BOM.

Keep this information real-time regarding inventory levels.

Automate procurement and replenishment.

Material wastes and keep stock levels optimum.

Material consumption tracking for better cost control.

Autonome warehousing optimization using barcode scanning and serial tracking.

4. Procurement and Vendor Management.

It perfectly procurement and enables smooth engineering operations.

Vendor evaluation and supplier relationship management.

Automated purchase orders and approvals.

Cost analysis and vendor performance tracking.

Integrated supply chain visibility.

Multiple suppliers handling for price comparison and risk mitigation.

Just-in-time (JIT) inventory to avoid excess stock.

5. Manufacturing and Production Management

ERPNext supports end-to-end manufacturing. Thus, ensuring smooth production cycles:

Automated work orders and job scheduling.

Machine and workforce efficiency monitoring.

Production costing and maintenance of quality standards.

Ease of tributary processes management.

Smoothing links between production and inventory.

Handling multiple location manufacturing units efficiently.

6. Quality Control and Compliance

Engineering firms have to maintain very high compliance with quality and compliance standards. ERPNext secures 1. Automatic quality checks and inspections.

Compliance tracking for regulations in the industry.

Standardized auditing and certifying reports.

Alerts in real time for any quality deviation.

Implementation of Six Sigma and Lean Manufacturing principles.

Ensuring regulatory adherence with ISO, CE, and other certifications.

7. Financial Management and Cost Control

Engineering businesses strictly have to ensure precise financial tracks. ERPNext delivers:

Full-fledged accounting and finance management.

Budget tracking and cost control mechanisms.

Automated billing and invoicing.

Financial reports and analytics in real-time.

Forecast tools for better cash flow management.

Tax compliance in multi currencies.

8. HR and Payroll Management

Efficiently handling a workforce is a must for an engineering company. Thus, ERPNext offers:

Attendance and shift scheduling of employees.

Payroll automation and tax compliance.

Performance analysis and training management.

Employee self-service portals.

Expense and leave management.

Automated timesheets for tracking employee efficiency.

Other ERPNext features engineer

Asset Management

Track and manage tools, machinery, and equipment.

Automate preventive maintenance schedules.

Extend asset lifecycle with predictive maintenance strategies.

Document and Compliance Management

Store and manage engineering drawings, blueprints, and manuals.

Provide document version control to prevent discrepancies.

Secure critical project documents with user access control.

Business Intelligence and Reporting

Generate real-time analytics that allow strategic decision-making.

Create customizable dashboards that monitor key performance indicators (KPIs).

AI-driven insights for optimum operational efficiency.

Conclusion

ERPNext is probably one of the most highly capable, reasonably-priced, and scalable ERP solutions especially designed for the engineering industry. ERPNext enables engineering firms to manage their operations, optimise resource and time efficiency, improve productivity, and comply with laws quite easily all on one integrated platform. Whether small or big engineering firms or organisations, employing ERPNext will definitely improve efficiency and take your business towards growth.

So, what are you waiting for? Transform your engineering operations with ERPNext! Contact our ERPExperts for assistance today!